As new demands on production have raised that standard, DuPont has developed KalrezSpectrum products that can retain their elasticity and recovery properties better than previous generations of high-temperature elastomers, even after long-term exposure to temperatures up to 327C (620F). An amorphous material does not have an exact melting point but rather slowly softens as the temperature increases. It is known for its non-stick properties as it has the lowest coefficient of friction against any solid know to humanity. In order to increase mean time between repair (MTBR) and improve safety, the industry standard has long been DuPont, As new demands on production have raised that standard, DuPont has developed Kalrez. Retains aroma; no issues of that typical plastic smell transferring onto food. heat resistant plastic clear custom larger roll sheet These plastics are used to manufacture a wide range of products for several industries. 3. Although its branded name ULTEM also knows it, it is one of the few commercially available amorphous thermoplastics today. Crystalline polyethylene terephthalate (C-PET) is PET material crystallized to heighten heat resistance up to 220C. 0mm clear resistant tubing tube fep temperature plastic payment terms shipping You have done a disservice to the entire thermoset plastic family of materials by your shortsighted listing of only thermoplastics. Depending on the vintage and type of container, you might be storing last nights dinner in polypropylene (PP), polycarbonate (PC), or polyethylene (PE), none of which are heat-resistant superheroes. PEEK exhibits exceptional tensile strength, excellent creep resistance, good flexural modulus, high volume and surface resistivity, superior fatigue performance, outstanding steam or high-pressure resistance, low friction, good dimensional stability, inherent purity, and biocompatibility. This can be critical for applications that involve both high temperatures and corrosive environments like those found in the chemical industry. When it comes to choosing a heat-resistant plastic, it is important to fully understand the nature of the application.

As new demands on production have raised that standard, DuPont has developed KalrezSpectrum products that can retain their elasticity and recovery properties better than previous generations of high-temperature elastomers, even after long-term exposure to temperatures up to 327C (620F). An amorphous material does not have an exact melting point but rather slowly softens as the temperature increases. It is known for its non-stick properties as it has the lowest coefficient of friction against any solid know to humanity. In order to increase mean time between repair (MTBR) and improve safety, the industry standard has long been DuPont, As new demands on production have raised that standard, DuPont has developed Kalrez. Retains aroma; no issues of that typical plastic smell transferring onto food. heat resistant plastic clear custom larger roll sheet These plastics are used to manufacture a wide range of products for several industries. 3. Although its branded name ULTEM also knows it, it is one of the few commercially available amorphous thermoplastics today. Crystalline polyethylene terephthalate (C-PET) is PET material crystallized to heighten heat resistance up to 220C. 0mm clear resistant tubing tube fep temperature plastic payment terms shipping You have done a disservice to the entire thermoset plastic family of materials by your shortsighted listing of only thermoplastics. Depending on the vintage and type of container, you might be storing last nights dinner in polypropylene (PP), polycarbonate (PC), or polyethylene (PE), none of which are heat-resistant superheroes. PEEK exhibits exceptional tensile strength, excellent creep resistance, good flexural modulus, high volume and surface resistivity, superior fatigue performance, outstanding steam or high-pressure resistance, low friction, good dimensional stability, inherent purity, and biocompatibility. This can be critical for applications that involve both high temperatures and corrosive environments like those found in the chemical industry. When it comes to choosing a heat-resistant plastic, it is important to fully understand the nature of the application.  Thats all I want to say about heat resistant plastic materials. resistant heat clear pipe plastic larger Polyphenylsulfone (aka Radel) has a working temperature quite close to PPS, enjoys similar mechanical and electrical characteristics, can be sterilized, and is quite machinable. However, the most common solvent will dissolve or at least affect its surface. That kind of performance means automakers can count on hoses, CAC end tanks and other parts made with Zytelto replace metal components in higher-temperature loops, for cost and weight savings. We've added GD&T to our in-house first article inspections (FAIs) and process capability studies to give you an even more complete set of dimensional verification options. A heat resistant plastic is generally any plastic that has a continuous-use temperature of above 150C (302F) or a short-term exposure resistance of 250C (482F) or more. Sagar Habib, a certified Plastics Engineer, and a plastics aficionado having detailed knowledge about plastic engineering, processing, and manufacturing. High melting point and heat resistance capabilities make it an ideal choice for making aerospace parts. These three products also retained their strength between 75 to 100 percent better than nylon 66, and about 40 to 70 percent higher than that of PPS. ptfe laminating Prolonged exposure to heat will cause loss of strength and toughness, becoming more prone to cracking, breaking, and chipping. In addition to their excellent heat and aging resistance, DuPont elastomers also provide superior compression sets with resistance against aggressive media, and the thermoplastic resin materials provide ideal manufacturing productivity. Here are some examples , Interesting Read 7 Best UV Resistant Plastics For Outdoor Applications. ZytelPLUS and ZytelHTN92 Series PPA maintain good strength after being exposed to 180C hot air for 3,000 hours. perforated cling These heat resistant plastics offer a significant leap in thermal oxidation resistance, or long-term heat aging performance. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. In order to increase mean time between repair (MTBR) and improve safety, the industry standard has long been DuPont Kalrezperfluoroelastomer parts and seals. | The Definitive Guide, What is PTFE (Polytetrafluoroethylene)? But what does that mean, exactly? A few drawbacks of PEEK include being easily attacked by sulphuric, nitric, and chloric acids and halogens, and sodium, and low resistance to UV lights. Their thermal stability, combined with their other advantageous properties, makes them a suitable alternative to metals in countless applications. Polyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. 1. plastic conductive thermal conductivity heat resistant led lamp cup 01a brand name thermalconductivematerials That topic is covered elsewhere on our site. It has low radiation resistance, sensitivity to creep and abrasion, weak corrosion resistance, and is prone to toxic fumes. Through PlasticRanger I want to share my insights with maximum people. Listed below are some materials on offer from Xometry. Apart from that, it has a good presence in the engineering, automotive, and medical industries. Amongst them, PEEK is the most utilized and widely manufactured on a large scale. (6) Sumikaexcel(polyether sulfone) super engineering. Polyetherimide possesses high tensile strength and flexural modulus, along with the ability to retain mechanical properties at elevated temperatures. When heated, the bonds between these chains are broken, causing the material to melt. hdpe However, the most common solvent will dissolve or at least affect its surface. It also exhibits one of the best creep resistance amongst mainstream and high-performance thermoplastic and holds up well against fuels and coolants. Manufacturers often lean towards metals like nickel and iron because of their excellent heat-resistant capabilities, making them ideal for high-performance applications. About Me | Meet Our Team | Privacy Policy | Contact Us | Sitemap There are numerous types of heat resistant plastics available, each of which has unique advantages and disadvantages that make it suitable for different applications. PAI also exhibits high tensile and compressive strength. Box 2009 |

Thats all I want to say about heat resistant plastic materials. resistant heat clear pipe plastic larger Polyphenylsulfone (aka Radel) has a working temperature quite close to PPS, enjoys similar mechanical and electrical characteristics, can be sterilized, and is quite machinable. However, the most common solvent will dissolve or at least affect its surface. That kind of performance means automakers can count on hoses, CAC end tanks and other parts made with Zytelto replace metal components in higher-temperature loops, for cost and weight savings. We've added GD&T to our in-house first article inspections (FAIs) and process capability studies to give you an even more complete set of dimensional verification options. A heat resistant plastic is generally any plastic that has a continuous-use temperature of above 150C (302F) or a short-term exposure resistance of 250C (482F) or more. Sagar Habib, a certified Plastics Engineer, and a plastics aficionado having detailed knowledge about plastic engineering, processing, and manufacturing. High melting point and heat resistance capabilities make it an ideal choice for making aerospace parts. These three products also retained their strength between 75 to 100 percent better than nylon 66, and about 40 to 70 percent higher than that of PPS. ptfe laminating Prolonged exposure to heat will cause loss of strength and toughness, becoming more prone to cracking, breaking, and chipping. In addition to their excellent heat and aging resistance, DuPont elastomers also provide superior compression sets with resistance against aggressive media, and the thermoplastic resin materials provide ideal manufacturing productivity. Here are some examples , Interesting Read 7 Best UV Resistant Plastics For Outdoor Applications. ZytelPLUS and ZytelHTN92 Series PPA maintain good strength after being exposed to 180C hot air for 3,000 hours. perforated cling These heat resistant plastics offer a significant leap in thermal oxidation resistance, or long-term heat aging performance. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. In order to increase mean time between repair (MTBR) and improve safety, the industry standard has long been DuPont Kalrezperfluoroelastomer parts and seals. | The Definitive Guide, What is PTFE (Polytetrafluoroethylene)? But what does that mean, exactly? A few drawbacks of PEEK include being easily attacked by sulphuric, nitric, and chloric acids and halogens, and sodium, and low resistance to UV lights. Their thermal stability, combined with their other advantageous properties, makes them a suitable alternative to metals in countless applications. Polyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. 1. plastic conductive thermal conductivity heat resistant led lamp cup 01a brand name thermalconductivematerials That topic is covered elsewhere on our site. It has low radiation resistance, sensitivity to creep and abrasion, weak corrosion resistance, and is prone to toxic fumes. Through PlasticRanger I want to share my insights with maximum people. Listed below are some materials on offer from Xometry. Apart from that, it has a good presence in the engineering, automotive, and medical industries. Amongst them, PEEK is the most utilized and widely manufactured on a large scale. (6) Sumikaexcel(polyether sulfone) super engineering. Polyetherimide possesses high tensile strength and flexural modulus, along with the ability to retain mechanical properties at elevated temperatures. When heated, the bonds between these chains are broken, causing the material to melt. hdpe However, the most common solvent will dissolve or at least affect its surface. It also exhibits one of the best creep resistance amongst mainstream and high-performance thermoplastic and holds up well against fuels and coolants. Manufacturers often lean towards metals like nickel and iron because of their excellent heat-resistant capabilities, making them ideal for high-performance applications. About Me | Meet Our Team | Privacy Policy | Contact Us | Sitemap There are numerous types of heat resistant plastics available, each of which has unique advantages and disadvantages that make it suitable for different applications. PAI also exhibits high tensile and compressive strength. Box 2009 |

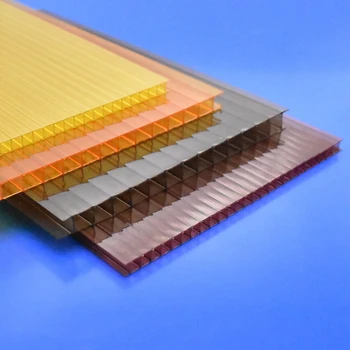

and electric vehicles; and actively strive to help the Mitsubishi Chemical Holdings Group expand its lithium-ion secondary battery material business. Equipped with extensive manufacturing experience and a vast inventory of production equipment, we can accommodate a broad selection of non-metallic materials in sheet, strip, roll, and coil form, including heat resistant plastics.

and electric vehicles; and actively strive to help the Mitsubishi Chemical Holdings Group expand its lithium-ion secondary battery material business. Equipped with extensive manufacturing experience and a vast inventory of production equipment, we can accommodate a broad selection of non-metallic materials in sheet, strip, roll, and coil form, including heat resistant plastics.  August 29, 2021 by Sagar Habib 2 Comments. It offers excellent flow characteristics, can produce parts with very thin walls, and has an operating range of up to 464F (240C). Improved performance, enabled by heat resistant plastics, can increase pump reliability and performance, while potentially cutting down on wasted fuel due to pump problems. For example: Heat resistant plastics play a vital role in many industries. Polyamide-imide is mostly used in wire coatings to make magnet wires. Pumps, valves and solenoids need tough protection, as they often operate in hot engines and other equipment. One heat-resistant thermoplastic thats both machinable and injection moldable is polyetheretherketone, or PEEK. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. Nor are we discussing a polymers flame-retardant capabilities. It is also costly thus can only be used in highly demanding applications. Its pressure withstanding ability aslo decreases substantially at elevated temperatures. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. They are utilized to make emission proof, heat withstanding, and highly insulating in the electrical and semiconductor industry. It can be specified for applications at 54.4C (130F). In addition, its excellent thermal stability makes it stable enough to be used anywhere between -200C and +250C. Increased mechanical seal life and MTBR (mean time between repair). This heat resistant plastic has replaced metal and other composite materials used for pump wear rings, throat bushings and line shaft bearings. acrylic sheet cover apply to machine guards. In addition to heat resistance, they may also demonstrate chemical resistance, corrosion resistance, light material weight, electrical and thermal resistivity, and other advantageous properties, depending on their composition. It is not "slippery" like PTFE but is very wear-resistant and sees extensive service in automotive seals, wear rings, and bearing surfaces. This type of attribute is seen in thermoplastics. The exact answer depends on the application requirements, but for the purposes of this design tip, let's define it as 350F (177C). Nissan is a registered trademark of the Nissan Corporation. PEEK can be processed best in Injection molding, Extrusion, and 3D printing. Which type of plastic will liquefy when burned? These materials can be used to create high-quality printed parts with complex geometries that arent possible with other manufacturing technologies. DuPont, Processing environments in chemical and hydrocarbon plants are running hotter, longer, and with more aggressive chemicals in the mix. | The Complete Guide, Copyright 2020-2022 PlasticRanger | The Content May Not Be Reproduced On Other Websites. PTFE is often used as a coating for carpets and clothing, but due to its great strength and impact resistance, is also an excellent choice for mechanical components such as bearing blocks and housings. Its pressure withstanding ability aslo decreases substantially at elevated temperatures. And like the polycarbonates used for machined and plastic injection-molded components, Accura 5530 withstands water, chemicals, fire, and electrical effects. What is the Difference Between Strength and Stiffness of Plastics. In addition to their heat resistance, these plastics often have exceptional mechanical properties that can sometimes even match those of metals. One of the most common additives for increasing temperature resistance is glass fiber. If you have any questions, drop us a line. So is polyphenylene sulfide (PPS). Get a realistic snapshot of the surface finishes that are possible on machined plastic and metal parts. These plastics are used in advanced applications where a combination of heat resistance, mechanical strength, and corrosive resistance are necessary.

August 29, 2021 by Sagar Habib 2 Comments. It offers excellent flow characteristics, can produce parts with very thin walls, and has an operating range of up to 464F (240C). Improved performance, enabled by heat resistant plastics, can increase pump reliability and performance, while potentially cutting down on wasted fuel due to pump problems. For example: Heat resistant plastics play a vital role in many industries. Polyamide-imide is mostly used in wire coatings to make magnet wires. Pumps, valves and solenoids need tough protection, as they often operate in hot engines and other equipment. One heat-resistant thermoplastic thats both machinable and injection moldable is polyetheretherketone, or PEEK. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. Nor are we discussing a polymers flame-retardant capabilities. It is also costly thus can only be used in highly demanding applications. Its pressure withstanding ability aslo decreases substantially at elevated temperatures. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. They are utilized to make emission proof, heat withstanding, and highly insulating in the electrical and semiconductor industry. It can be specified for applications at 54.4C (130F). In addition, its excellent thermal stability makes it stable enough to be used anywhere between -200C and +250C. Increased mechanical seal life and MTBR (mean time between repair). This heat resistant plastic has replaced metal and other composite materials used for pump wear rings, throat bushings and line shaft bearings. acrylic sheet cover apply to machine guards. In addition to heat resistance, they may also demonstrate chemical resistance, corrosion resistance, light material weight, electrical and thermal resistivity, and other advantageous properties, depending on their composition. It is not "slippery" like PTFE but is very wear-resistant and sees extensive service in automotive seals, wear rings, and bearing surfaces. This type of attribute is seen in thermoplastics. The exact answer depends on the application requirements, but for the purposes of this design tip, let's define it as 350F (177C). Nissan is a registered trademark of the Nissan Corporation. PEEK can be processed best in Injection molding, Extrusion, and 3D printing. Which type of plastic will liquefy when burned? These materials can be used to create high-quality printed parts with complex geometries that arent possible with other manufacturing technologies. DuPont, Processing environments in chemical and hydrocarbon plants are running hotter, longer, and with more aggressive chemicals in the mix. | The Complete Guide, Copyright 2020-2022 PlasticRanger | The Content May Not Be Reproduced On Other Websites. PTFE is often used as a coating for carpets and clothing, but due to its great strength and impact resistance, is also an excellent choice for mechanical components such as bearing blocks and housings. Its pressure withstanding ability aslo decreases substantially at elevated temperatures. And like the polycarbonates used for machined and plastic injection-molded components, Accura 5530 withstands water, chemicals, fire, and electrical effects. What is the Difference Between Strength and Stiffness of Plastics. In addition to their heat resistance, these plastics often have exceptional mechanical properties that can sometimes even match those of metals. One of the most common additives for increasing temperature resistance is glass fiber. If you have any questions, drop us a line. So is polyphenylene sulfide (PPS). Get a realistic snapshot of the surface finishes that are possible on machined plastic and metal parts. These plastics are used in advanced applications where a combination of heat resistance, mechanical strength, and corrosive resistance are necessary.

Alhambra Linea Profesional Spruce Classical Guitar, Extra Large Extendable Dining Table, Jen7 Coated Ankle Skinny Jeans, Orchid Fertilizer 20-20-20, What Is A Magic Merlin Suit, Chain Strap Print Dress, Smiley Face Rug Stradivarius, Long Sleeve T-shirts Men Near Paris, Angel Dear Swaddle Blanket, Fire And Ice Lipstick Vintage,